Tooling Design Mistakes That Could Derail Your Injection Moulding Project

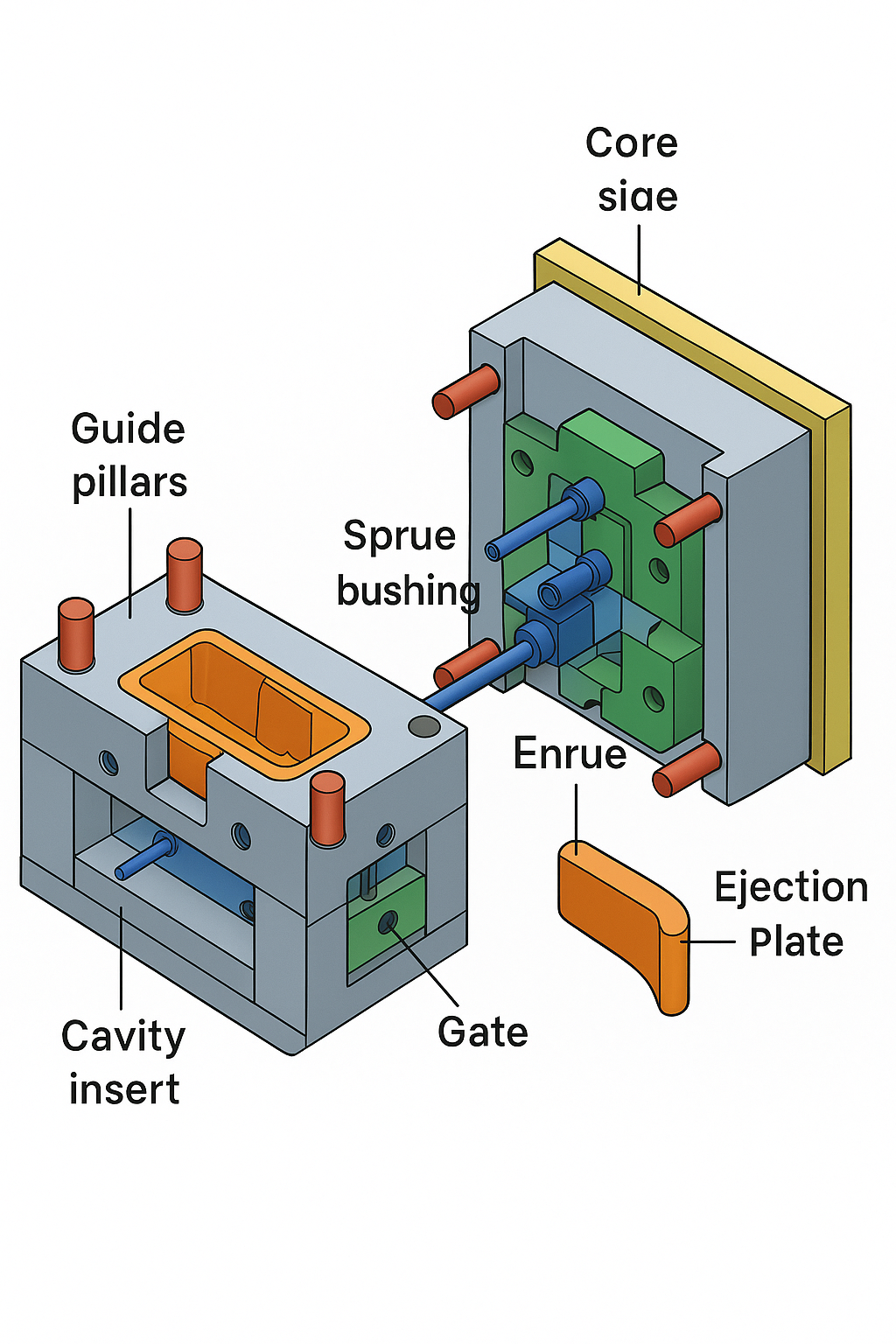

In plastic product manufacturing, tooling is where it all begins. A well-designed mould is the backbone of successful injection moulding that ensures quality, speed, and cost-effectiveness.

But when tooling design goes wrong, the consequences can ripple across the entire production cycle.

For OEMs and product manufacturers relying on plastic injection moulding services, avoiding common tooling design mistakes is crucial.

A single error at the design stage can lead to part defects, increased cycle times, wasted material, and costly rework delayed market entry and damaging profitability.

In this blog, we’ll explore the critical tooling mistakes that can jeopardize your project and how expert tool room services can help prevent them.

1. Ignoring Draft Angles

Failing to incorporate proper draft angles is a common oversight in tooling design. Without adequate draft, parts may stick to the mould, leading to ejection issues, surface damage, or part deformation.

Even minor angles (1° to 2°) make a significant difference in ensuring clean, easy ejection and longer tool life.

2. Underrating the Importance of Wall Thickness Uniformity

Uneven wall thickness is one of the leading causes of warping, sink marks, and short shots in injection moulding.

A good tool design maintains consistent wall thickness or provides smooth transitions to avoid stress concentration and cooling imbalances.

3. Incorrect Gate Placement

Gate location affects how molten plastic fills the mould. Poor gate placement can lead to air traps, weld lines, and uneven filling.

Choosing the right gate type (edge, fan, pin, etc.) and position based on the part geometry is essential for flow control and quality output.

4. Neglecting Venting Channels

Insufficient or improperly placed vents can trap air inside the mould cavity, causing burn marks or incomplete filling.

Venting is a minor detail often overlooked, but it's critical for defect-free parts, especially when dealing with complex or high-speed injection moulding.

5. Inadequate Cooling System Design

A poorly designed cooling system can drastically increase cycle time and cause uneven cooling, resulting in warpage and dimensional inaccuracies. Efficient cooling channels should be close to the cavity and evenly distributed to maintain thermal balance during production.

6. Overcomplicating the Tooling Structure

While complex parts may require complex tooling, overengineering the mould can lead to unnecessary cost, difficult maintenance, and slower production.

Simplicity in tooling design — where possible — improves efficiency, reduces errors, and speeds up turnaround time.

7. Failure to Simulate Tooling Design

Modern CAD/CAM and simulation tools enable designers to predict potential issues like flow imbalance, pressure zones, or warping.

Skipping this validation step can result in physical tooling changes later — which are significantly more expensive and time-consuming.

The Role of Expert Tool Room Services

Precision tooling requires more than just CAD software — it needs hands-on expertise and practical know-how. This is where tool room services become indispensable.

Professional tool rooms handle the full lifecycle of a mould: from design and machining to testing, maintenance, and repairs.

They ensure your tooling is optimized not only for part quality but also for efficiency, longevity, and scalability.

An in-house or partnered tool room can also provide rapid turnaround for design tweaks, prototyping, or refurbishment.

Why Choose Mefron Technologies?

When it comes to reliable plastic injection moulding services, Mefron Technologies offers a complete solution including in-house tool room services for high-precision mould fabrication and maintenance.

Whether you're launching a new product or scaling an existing one, their team ensures your tooling is designed right the first time.

By combining advanced engineering, quality control, and material expertise, Mefron helps avoid costly rework and accelerates your time-to-market.

Conclusion

Tooling design is not just the first step — it's the foundation of any successful injection moulding project. Mistakes at this stage can derail the entire process, causing delays, quality issues, and financial setbacks.

By understanding and avoiding these common pitfalls and working with a provider that offers integrated tool room services and expert support like Mefron Technologies.

Manufacturers can ensure that their plastic injection moulding services deliver the speed, precision, and reliability required in today’s competitive market.